Mutoh XpertJet 1641SR Pro | 64" CMYK | Eco-Solvent Printer

The Mutoh XpertJet 1641SR Pro 64” Eco-Solvent single head, 4-color (CMYK) printer, builds upon Mutoh’s made in Japan reputation and delivers superior print quality and outstanding speeds at an affordable price. It is powered by Mutoh’s new genuine VerteLith™ RIP Software, bundled with FlexiDESIGNER Mutoh Edition 21, a $2,199.00 value. VerteLith RIP optimizes all of the capabilities the XPJ-1641SR Pro has to offer and produces the best-possible gradients, skin tones and vivid colors. This printer features Mutoh’s new AccuFine Print Head, which achieves best-in-class dot placement accuracy and an increased nozzle row length for 35% faster print speeds.

In addition, the XPJ-1641SR Pro is paired with Mutoh’s GREENGUARD Gold certified MS41 Eco-Solvent ink, suitable for use in sensitive environments such as hospitals, child care facilities and more, all while providing users a larger color gamut, outstanding durability, and improved dot gain.

The System Includes the Following:

- 64" Mutoh XpertJet 1641SR Pro Eco-Solvent Printer

- Set of Mutoh MS41 Eco-Solvent Ink

- VerteLith™ RIP Software

- FlexiDESIGNER Mutoh Edition 21

Amazing Jetting Performance

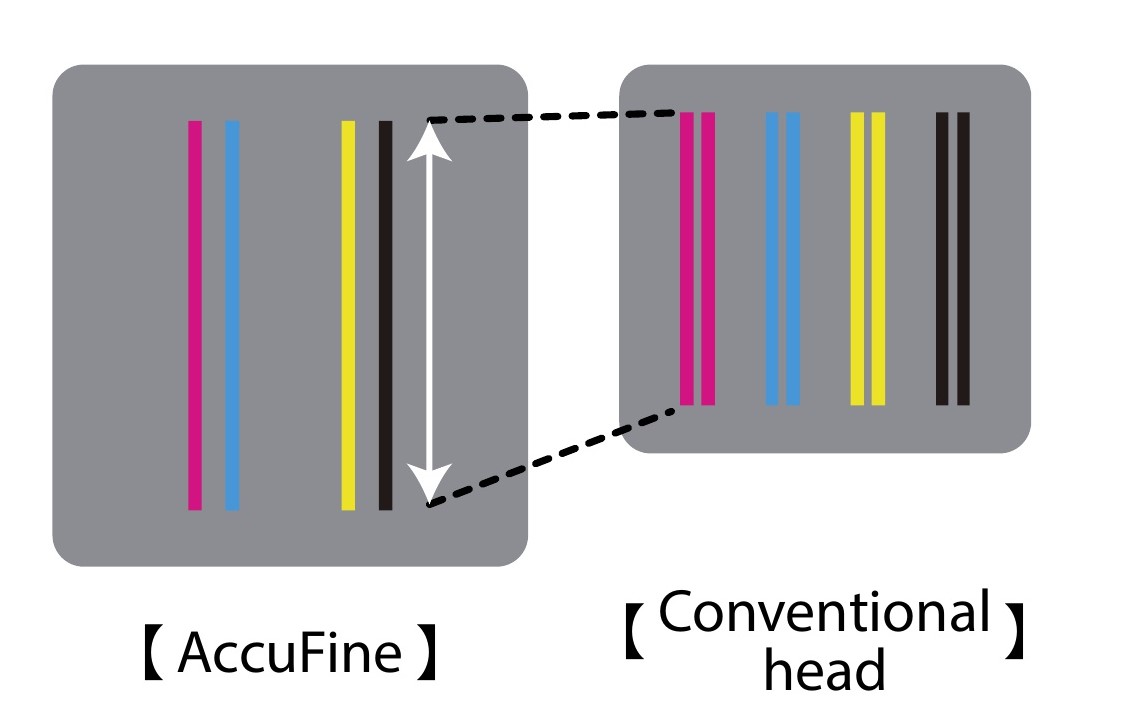

Equipped with AccuFine, the newly released wide high-density piezo head exclusively for Mutoh Through large-scale, high-precision, and dramatic improvements in bullet impact accuracy, Achieved both high-speed work and high image quality. There is little banding even when printing at high speeds. It is possible to create images with deep expressive power. The new head has a 33% increased nozzle length and 165% improved high-concentration nozzle spacing. It shows more than twice the accuracy of bullet impact compared to existing models.

i-screen Technology - New Printing Effect

It was created with MUTOH’s proprietary Intelligent Interweave printing technology. Through dot arrangement that takes into account the human gaze. Banding is reduced and output images are expressed more smoothly.

Automatic Nozzle Inspection and Nozzle Selection Function

The new automatic inspection technology can detect clogged printhead nozzles and automatically performs cleaning cycles to recover the printheads optimum printing performance.

[With automatic nozzle check, a built-in sensor recognizes nozzle clogging.]

[When nozzle clogging is detected, the automatic cleaning cycle is performed. Successful nozzle recovery will resume printing.]

Nozzle Area Select Technology

If the nozzle clogging is not repaired, only the active nozzles are screened to continue printing. You can reduce the amount of time your work is down. In addition, the automatic nozzle inspection and nozzle selection function reduces errors during unattended/overnight operation.

Precise Worry-Free Media Selection Lever

Reduce the worry of media selection by adjusting the pressure on the media in 4 steps. In addition, thin paper or soft media can also be used.

Multi-Step Pressurization System

Improve the feeding stability of various media. With Mutoh's original multi-stage pressurization mechanism, even thin roll media can be fed smoothly.

DropMaster 2 (Automatic Bi-Directional Alignment with Built-in Color Sensor)

XpertJet has a built-in color sensor for automatic bi-directional alignment, saving you precious time and increasing your efficiency.

[Without DropMaster2 Applied.]

[DropMaster2 Applied.]

Feed Master System (Automatic Media Feed Adjustment)

Print a print pattern and read it by the color sensor on the carriage to automate the paper feed correction. It reduces labor and media loss in the adjustment process.

Media Tracker System (Media Roll Balance Management)

Recognizes the remaining amount of paper by reading the barcode printed on the media after loading the media. Streamline the management of multiple media.

New Media Flange for Quick and Super Easy Installation

Replace media paper rolls with ease. Offers users more convenience in replacing media.